New Viable System of Making Ethanol

In United States several, cars and trucks tend to run on a mixture of 90% gasoline and 10% Ethanol which is a renewal fuel produced mainly from fermented corn. However, producing 14 billion gallons of ethanol used yearly by the American drivers needs millions of acres of farmland. According to a recent unearthing by the scientists of Stanford University has led to a new viable system of making ethanol without the need of corn or any other crops.

The technology tends to have three basic components, namely water, carbon dioxide and electricity which are delivered through a copper substance. The results had been published in Proceedings of the national Academy of Sciences. Thomas Jaramillo, study principal investigator, an associate professor of chemical engineering at Stanford and of photon science at the SLAC National Accelerator Laboratory, had commented that one of their long range aims was to produce renewable ethanol in a manner which does not impact the global food supply. He added that copper is said to be one of the few substances which could produce ethanol at room temperature. One could only feed it electricity, water and carbon dioxide and it can make ethanol.

Diverse Facets of Copper – Affect Electro Catalytic Performance

The issue is that it also tends to make 15 other compounds at the same time inclusive of lower-value products such as methane and carbon monoxide. Segregating these products would be expensive together with plenty of energy. Scientists would prefer to design copper substances which tend to selectively convert carbon dioxide into higher-value chemicals and fuels, such as ethanol and propanol with less or no by-products. However the clear understanding of how these substances tend to really work need to be known and it is here where the recent discovery tends to come in.

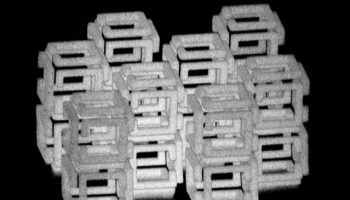

The Stanford team for the PNAS study chose three samples of crystalline copper called copper (100) copper (111) and copper (751). Scientists tend to utilise these numbers to define the surface geometries of individual crystals. Though the main differences by way of their atoms seems arranged on the surface, copper 100, 111 and 751 tend to appear virtually identical according to an associate staff scientist at SLAC and co-lead main author of the study, Christopher Hahn. He informed that the essence of the work was to comprehend how these diverse facets of copper seem to affect electro catalytic performance.

Novel Method Ethanol – Growing Single Crystal-Like Copper

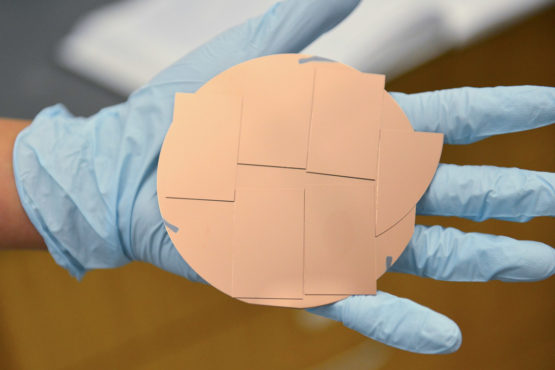

The scientists in their earlier studies had developed individual crystal copper electrodes about 1-square millimetre in size. Hahn together with his co-workers at SLAC had created a novel method of growing single crystal-like copper over large wafers of silicon and sapphire for this study. This system led to films of individual form of copper with a surface of 6-square centimetre, which was 600 times bigger than usual single crystals.

The researchers in order to compare electro catalytic performance, placed the three large electrodes in water exposing them to carbon dioxide gas, applied a prospective in order to generate electric current. When the team had applied a particular voltage, the electrodes made of copper – 751 seemed to be more selective to liquid products like ethanol and propanol than those made of copper – 100 or 111.